OUR-SERVICES

CONTRACTORS

Flooring and Waterproofing

EXPLORE THE FEATURES

Epoxy Floor Systems

Epoxy Resin Screed is typically applied at thicknesses between 2mm – 3mm for self smoothing and 4mm – 6mm for trowel applied systems.

EXPLORE THE FEATURES

Polyurethane Resin Screed

Typically applied at thicknesses between 3mm – 5mm for Self-Smoothing and 6mm – 9mm for Trowel Applied Systems.

EXPLORE THE FEATURES

Polished Decorative Concrete

Decorative internal floors and walls with a wide range of colours

EXPLORE THE FEATURES

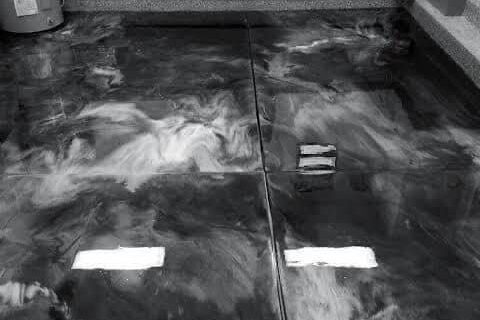

Marble Epoxy

As with any metallic marble epoxy floor, the marble effect is from the metallic that’s added to the epoxy.

EXPLORE THE FEATURES

Water-proofing

Our waterproofing techniques builds an impenetrable barrier over foundations, roofs, and walls against water

FLOORING SOLUTIONS

Professional Epoxy Flooring

Experienced with real focus on customer satisfaction, you can rely on us for your next floor renovation, new installation or home repair. We provide a professional service for private and commercial customers.

Projects

3d epoxy EPOXY FLOORING

3D EPOXY FLOORING IN KENYA

We supply and apply 3d epoxy flooring services for residential and commercial floors in Kenya.

EPOXY FLOORING

MARBLE EPOXY FLOOR COATINGS

Epoxy coatings can be applied over any concrete as long as the surface is structurally sound and prepared properly.

EPOXY FLOORING Industrial

MILLERS PROCESSING INDUSTRY

Very high resistance to frequent contact with chemical substances

EPOXY FLOORING Industrial

TEA PROCESSING INDUSTRY

The better the durability of a floor, the higher the chances are of sanitary conditions.

EPOXY FLOORING Industrial

AVOCADO PROCESSING INDUSTRY

A hygienic surface is vital in establishing a safe, efficient, and government-approved food processing plant.

EPOXY FLOORING Industrial

LABORATORY EPOXY FLOORING IN KENYA

Because it can meet and even surpass industry standards, epoxy flooring is the prefered option for laboratories all over the world. Because of its non-porous surface, this seamless and hygienic epoxy flooring option—one of many on the market—is perfect for […]

EPOXY FLOORING Industrial

WAREHOUSE EPOXY FLOOR COATING

We supply high quality epoxy flooring services and kits to commercial sectors. Reach out to us for warehouse, industrial, and hotel flooring coatings.

EPOXY FLOORING Industrial

EPOXY FLOORING FOR AUTOMOTIVE INDUSTRIES

From the assembly line to the showroom floor and every place in between, facilities that manufacture, sell, and repair automobiles must be equipped with flooring systems that can handle the unique demands of epoxy flooring for automotive industries. Concrete slabs […]

Featured

Explore the features

Painting Services

Our Professional painting services includes interior & exterior house painting, commercial painting, epoxy wall paint, drywall repair & more. Get a quote today!

Explore the features

Water-proofing

Dampness-waterproofing, Exterior wall-waterproofing, roof water-proofing, bathroom-waterproofing, basement water-proofing, water tank-waterproofing

Explore the features

Polished Decorative Concrete

A polished concrete floor has a glossy, mirror-like finish. The design options for polished concrete are vast. You can choose nearly any color

Explore the Features

Our Mission

We promote a Customer for Life culture that emphasizes outstanding service and meets our commitments at every level of our company. .

COMPLETED

WORKS

FLOORING

CLIENTS

WATERPROOF

CLIENTS

PAINTING

CLIENTS

DIRECTROR

R.M

“I’ve had the privilege to work with Epoxy Africa since 2020, during which time they have provided an excellent team of well-established and experienced professionals. Their work on the Hema Hospital maternity and theatre epoxy floor project was outstanding, as was their level of professionalism, attentiveness, attitude and performance. Their ability to perform under budget and ahead of schedule.”

Quality Surveyor

Mary Wambui

“I have found Epoxy Africa to be a responsible, organized and timely contractor that works proactively to resolve potential issues before they occur. In my experience, they have always conducted themselves with the highest level of integrity. I would absolutely recommend them for public works or private projects.”

PRINCIPAL

Sr. Martha

“It is a rarity to see owner’s personally involved with any project of any size but Stephen and Agnes, the company’s two owners and principals were intimately involved with the project at Koru mission hospital from beginning to the end. They provided assurances along the way that the project would be completed on time and lived up to this challenging commitment.”

Mapei Engineer

Viviane.A

“They know their business and their approach and manner of doing business works well as a team player with the owners and their other consultants. Epoxy Africa knows their business well and as such can in many cases lend their expertise to the various industries in need of Epoxy.”

Site Visit

We do site visit then take measurements and check floor conditions.

Project plan

Our professional team will go through the requirements necessary to complete the project successfully.

Floor preparation

-Hack off loose and friable flooring, dirt and debris to be packed in Hessian bags and to be carted off

site.

-Strip off the worn out expansion joint

- Fill and repair the holes and broken areas in the floor to ensure the screed is suitable and level.

.-Grind the floor using a diamond-cut grinding machine, to ensure opening of cementitious pores

to increase adhesion and remove laitance.

-Clean the floor by sweeping to get rid of the dust particles generated from grinding.

-Again clean the floor by sweeping to get rid of the dust particles.

Epoxy Resin Installation

-Prime the surface with an epoxy primer by use of roller/squeegee/trowel and allow to cure for

at least 8 hours.

-Thereafter apply the self-leveling epoxy system at the recommended thickness using a calibrated notched rake and trowel and back roll with spiked roller to deaerate and smoothen

the finish. (Base+hardener+pigment+filler).